As of January 13, 2026, the semiconductor landscape has reached a historic inflection point. Intel Corporation (NASDAQ: INTC) has officially announced that its 18A (1.8nm-class) manufacturing node has reached high-volume manufacturing (HVM) status at its Fab 52 facility in Arizona. This milestone marks the triumphant conclusion of CEO Pat Gelsinger’s ambitious "five nodes in four years" strategy, a multi-year sprint designed to restore the American giant to the top of the process technology ladder. By successfully scaling 18A, Intel has effectively closed the performance gap with its rivals, positioning itself as a formidable alternative to the long-standing dominance of Asian foundries.

The immediate significance of the 18A rollout extends far beyond corporate pride; it is the fundamental hardware bedrock for the 2026 AI revolution. With the launch of the Panther Lake client processors and Clearwater Forest server chips, Intel is providing the power-efficient silicon necessary to move generative AI from massive data centers into localized edge devices and more efficient cloud environments. The move signals a shift in the global supply chain, offering Western tech giants a high-performance, U.S.-based manufacturing partner at a time when semiconductor sovereignty is a top-tier geopolitical priority.

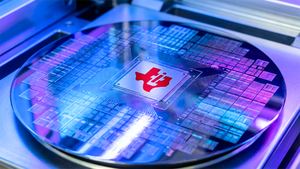

The Twin Engines of Leadership: RibbonFET and PowerVia

The technical superiority of Intel 18A rests on two revolutionary pillars: RibbonFET and PowerVia. RibbonFET represents Intel’s implementation of Gate-All-Around (GAA) transistor architecture, which replaces the FinFET design that has dominated the industry for over a decade. By wrapping the transistor gate entirely around the channel with four vertically stacked nanoribbons, Intel has achieved unprecedented control over the electrical current. This architecture drastically minimizes power leakage—a critical hurdle as transistors approach the atomic scale—allowing for higher drive currents and faster switching speeds at lower voltages.

Perhaps more significant is PowerVia, Intel’s industry-first implementation of backside power delivery. Traditionally, both power and signal lines competed for space on the front of a wafer, leading to a "congested mess" of wiring that hindered efficiency. PowerVia moves the power delivery network to the reverse side of the silicon, separating the "plumbing" from the "signaling." This architectural leap has resulted in a 6% to 10% frequency boost and a significant reduction in "IR droop" (voltage drop), allowing chips to run cooler and more efficiently. Initial reactions from the IEEE and semiconductor analysts have been overwhelmingly positive, with many experts noting that Intel has effectively "leapfrogged" TSMC (NYSE: TSM), which is not expected to integrate similar backside power technology until its N2P or A16 nodes later in 2026 or 2027.

A New Power Dynamic for AI Titans and Foundries

The success of 18A has immediate and profound implications for the world's largest technology companies. Microsoft Corp. (NASDAQ: MSFT) has emerged as a primary anchor customer, utilizing the 18A node for its next-generation Maia 2 AI accelerators. This partnership allows Microsoft to reduce its reliance on external chip supplies while leveraging Intel’s domestic manufacturing to satisfy "Sovereign AI" requirements. Similarly, Amazon.com Inc. (NASDAQ: AMZN) has leveraged Intel 18A for a custom AI fabric chip, highlighting a trend where hyper-scalers are increasingly designing their own silicon but seeking Intel’s advanced nodes for fabrication.

For the broader market, Intel’s resurgence puts immense pressure on TSMC and Samsung Electronics (KRX: 005930). For the first time in years, major fabless designers like NVIDIA Corp. (NASDAQ: NVDA) and Broadcom Inc. (NASDAQ: AVGO) have a viable secondary source for leading-edge silicon. While Apple remains closely tied to TSMC’s 2nm (N2) process, the competitive pricing and unique power-delivery advantages of Intel 18A have forced a pricing war in the foundry space. This competition is expected to lower the barrier for AI startups to access high-performance custom silicon, potentially disrupting the current GPU-centric monopoly and fostering a more diverse ecosystem of specialized AI hardware.

Redefining the Global AI Landscape

The arrival of 18A is more than a technical achievement; it is a pivotal moment in the broader AI narrative. We are moving away from the era of "brute force" AI—where performance was gained simply by adding more power—to an era of "efficient intelligence." The thermal advantages of PowerVia mean that the next generation of AI PCs can run sophisticated large language models (LLMs) locally without exhausting battery life or requiring noisy cooling systems. This shift toward edge AI is crucial for privacy and real-time processing, fundamentally changing how consumers interact with their devices.

Furthermore, Intel’s success serves as a proof of concept for the CHIPS and Science Act, demonstrating that large-scale industrial policy can successfully revitalize domestic high-tech manufacturing. When compared to previous industry milestones, such as the introduction of High-K Metal Gate at 45nm, the 18A node represents a similar "reset" of the competitive field. However, concerns remain regarding the long-term sustainability of the high yields required for profitability. While Intel has cleared the technical hurdle of production, the industry is watching closely to see if they can maintain the "Golden Yields" (above 75%) necessary to compete with TSMC’s legendary manufacturing consistency.

The Road to 14A and High-NA EUV

Looking ahead, the 18A node is merely the foundation for Intel’s long-term roadmap. The company has already begun installing ASML’s Twinscan EXE:5200 High-NA EUV (Extreme Ultraviolet) lithography machines in its Oregon and Arizona facilities. These multi-hundred-million-dollar machines are essential for the next major leap: the Intel 14A node. Expected to enter risk production in late 2026, 14A will push feature sizes down to 1.4nm, further refining the RibbonFET architecture and likely introducing even more sophisticated backside power techniques.

The challenges remaining are largely operational and economic. Scaling High-NA EUV is an unmapped territory for the industry, and Intel is the pioneer. Experts predict that the next 24 months will be characterized by an intense focus on "advanced packaging" technologies, such as Foveros Direct, which allow 18A logic tiles to be stacked with memory and I/O from other nodes. As AI models continue to grow in complexity, the ability to integrate diverse chiplets into a single package will be just as important as the raw transistor size of the 18A node itself.

Conclusion: A New Era of Semiconductor Competition

Intel's successful ramp of the 18A node in early 2026 stands as a defining moment in the history of computing. By delivering on the "5 nodes in 4 years" promise, the company has not only saved its own foundry aspirations but has also injected much-needed competition into the leading-edge semiconductor market. The combination of RibbonFET and PowerVia provides a genuine technical edge in power efficiency, a metric that has become the new "gold standard" in the age of AI.

As we look toward the remainder of 2026, the industry's eyes will be on the retail and enterprise performance of Panther Lake and Clearwater Forest. If these chips meet or exceed their performance-per-watt targets, it will confirm that Intel has regained its seat at the table of process leadership. For the first time in a decade, the question is no longer "Can Intel catch up?" but rather "How will the rest of the world respond to Intel's lead?"

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.