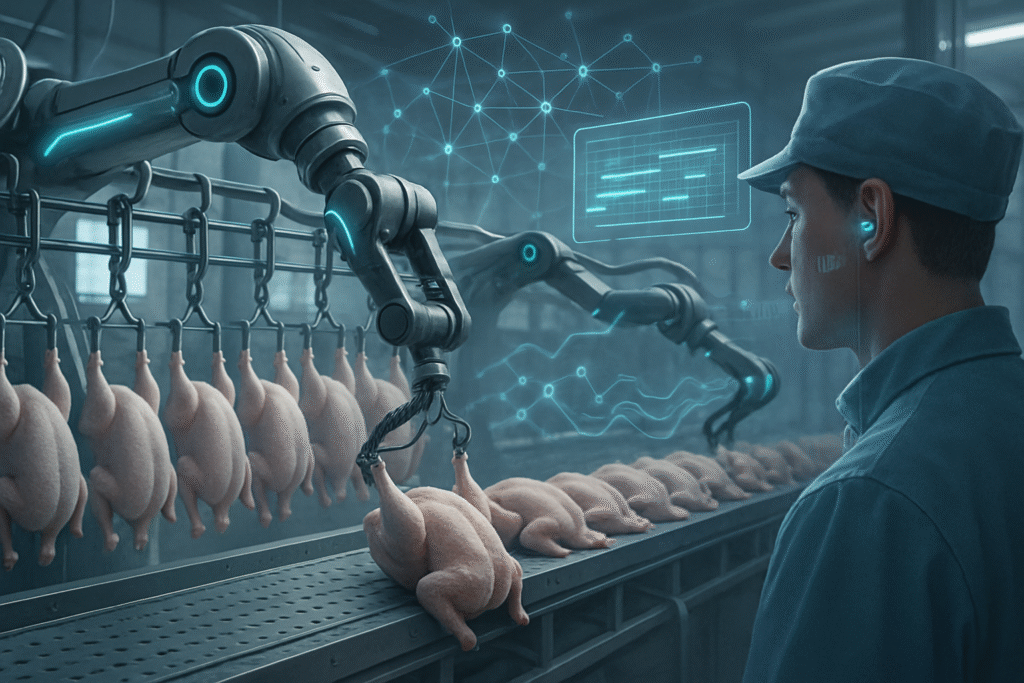

The global poultry processing industry is undergoing a profound transformation, propelled by the latest advancements in Artificial Intelligence. At the forefront of this revolution are sophisticated AI-powered predictive scheduling systems and intuitive voice-activated assistants, fundamentally reshaping how poultry products are brought to market. These innovations promise to deliver unprecedented levels of efficiency, food safety, and sustainability, addressing critical challenges faced by producers worldwide.

The immediate significance of these AI deployments lies in their ability to optimize complex operations from farm to fork. Predictive scheduling, leveraging advanced machine learning, ensures that production aligns perfectly with demand, minimizing waste and maximizing resource utilization. Simultaneously, voice-activated assistants, powered by conversational AI, empower factory workers with hands-free, real-time information and guidance, significantly boosting productivity and streamlining workflows in fast-paced environments. This dual approach marks a pivotal moment, moving the industry from traditional, often reactive, methods to a proactive, data-driven paradigm, poised to meet escalating global demand for poultry products efficiently and ethically.

Unpacking the Technical Revolution: From Algorithms to Conversational AI

The technical underpinnings of AI in poultry processing represent a leap forward from previous approaches. Predictive scheduling relies on a suite of sophisticated machine learning models and neural networks. Algorithms such as regression techniques (e.g., linear regression, support vector regression) analyze historical production data, breed standards, environmental conditions, and real-time feed consumption to forecast demand and optimize harvest schedules. Deep learning models, including Convolutional Neural Networks (CNNs) like YOLOv8, are deployed for real-time monitoring, such as accurate chicken counting and health issue detection through fecal image analysis (using models like EfficientNetB7). Backpropagation Neural Networks (BPNNs) and Support Vector Machines (SVMs) are used to classify raw poultry breast myopathies with high accuracy, far surpassing traditional statistical methods. These AI systems dynamically adjust schedules based on live data, preventing overproduction or shortages, a stark contrast to static, assumption-based manual planning.

Voice-activated assistants, on the other hand, are built upon a foundation of advanced Natural Language Processing (NLP) and Large Language Models (LLMs). The process begins with robust Speech-to-Text (STT) technology (Automatic Speech Recognition – ASR) that converts spoken commands into text, capable of handling factory noise and diverse accents. NLP then interprets the user's intent and context, even with nuanced language, through Natural Language Understanding (NLU). Finally, Natural Language Generation (NLG) and LLMs (like those from OpenAI) craft coherent, contextually aware responses. This allows for natural, conversational interactions, moving beyond the rigid, rule-based systems of traditional Interactive Voice Response (IVR). The hands-free operation in often cold, wet, and gloved environments is a significant technical advantage, providing instant access to information without interrupting physical tasks.

Initial reactions from the AI research community and industry experts have been overwhelmingly positive. Industry professionals view these advancements as essential for competitiveness, food safety, and yield improvement, emphasizing the need for "digital transformation" and breaking down "data silos" within the Industry 4.0 framework. Researchers are actively refining algorithms for computer vision (e.g., advanced object detection for monitoring), machine learning (e.g., myopathy detection), and even vocalization analysis for animal welfare. Both groups acknowledge the challenges of data quality and the need for explainable AI models to build trust, but the consensus is that these technologies offer unprecedented precision, real-time control, and predictive capabilities, fundamentally reshaping the sector.

Corporate Flight Paths: Who Benefits in the AI Poultry Race

The integration of AI in poultry processing is creating a dynamic landscape for AI companies, tech giants, and startups, reconfiguring competitive advantages and market positioning. Specialized AI companies focused on industrial automation and food tech stand to benefit immensely by providing bespoke solutions, such as AI-powered vision systems for quality control and algorithms for predictive maintenance.

Tech giants, while not always developing poultry-specific AI directly, are crucial enablers. Companies like Google (NASDAQ: GOOGL) and Microsoft (NASDAQ: MSFT) provide the foundational AI infrastructure, cloud computing services, and general AI/ML platforms that power these specialized applications. Their ongoing large-scale AI research and development indirectly contribute to the entire ecosystem, creating a fertile ground for innovation. The increasing investment in AI across manufacturing and supply chain operations, projected to grow significantly, underscores the opportunity for these core technology providers.

Startups are particularly well-positioned to disrupt existing practices with agile, specialized solutions. Venture arms of major food corporations, such as Tyson Ventures (from Tyson Foods, NYSE: TSN), are actively partnering with and investing in startups focusing on areas like food waste reduction, animal welfare, and efficient logistics. This provides a direct pathway for innovative young companies to gain traction and funding. Companies like BAADER (private), with its AI-powered ClassifEYE vision system, and Cargill (private), through innovations like 'Birdoo' developed with Knex, are leading the charge in deploying intelligent, learning tools for real-time quality control and flock insights. Other significant players include Koch Foods (private) utilizing AI for demand forecasting, and AZLOGICA® (private) offering IoT and AI solutions for agricultural optimization.

This shift presents several competitive implications. There's an increased demand for specialized AI talent, and new vertical markets are opening for tech giants. Companies that can demonstrate positive societal impact (e.g., sustainability, animal welfare) alongside economic benefits may gain a reputational edge. The massive data generated will drive demand for robust edge computing and advanced analytics platforms, areas where tech giants excel. Furthermore, the potential for robust, industrial-grade voice AI solutions, akin to those seen in fast-food drive-thrus, creates opportunities for companies specializing in this domain.

The disruption to existing products and services is substantial. AI-driven robotics are fundamentally altering manual labor roles, addressing persistent labor shortages but also raising concerns about job displacement. AI-powered vision systems are disrupting conventional, often slower, manual quality control methods. Predictive scheduling is replacing static production plans, leading to more dynamic and responsive supply chains. Reactive disease management is giving way to proactive prevention through real-time monitoring. The market will increasingly favor "smart" machinery and integrated AI platforms over generic equipment and software. This leads to strategic advantages in cost leadership, differentiation through enhanced quality and safety, operational excellence, and improved sustainability, positioning early adopters as market leaders.

A Wider Lens: AI's Footprint in the Broader World

AI's integration into poultry processing is not an isolated event but a significant component within broader AI trends encompassing precision agriculture, industrial automation, and supply chain optimization. In precision agriculture, AI extends beyond crop management to continuous monitoring of bird health, behavior, and microenvironments, detecting issues earlier than human observation. Within industrial automation, AI transforms food manufacturing lines by enabling robots to perform precise, individualized tasks like cutting and deboning, adapting to the biological variability of each bird – a challenge that traditional, rigid automation couldn't overcome. For the supply chain, AI is pivotal in optimizing demand forecasting, inventory management, and logistics, ensuring product freshness and reducing waste.

The broader impacts are far-reaching. Societally, AI enhances food safety, addresses labor shortages in demanding roles, and improves animal welfare through continuous, data-driven monitoring. Economically, it boosts efficiency, productivity, and profitability, with the AI-driven food tech market projected for substantial growth into the tens of billions by 2030. Environmentally, AI contributes to sustainability by reducing food waste through accurate forecasting and optimizing resource consumption (feed, water, energy), thereby lowering the industry's carbon footprint.

However, these advancements are not without concerns. Job displacement is a primary worry, as AI-driven automation replaces manual labor, necessitating workforce reskilling and potentially impacting rural communities. Ethical AI considerations include algorithmic bias, the need for transparency in "black box" models, and ensuring responsible use, particularly concerning animal welfare. Data privacy is another critical concern, as vast amounts of data are collected, raising questions about collection, storage, and potential misuse, demanding robust compliance with regulations like GDPR. High initial investment and the need for specialized technical expertise also pose barriers for smaller producers.

Compared to previous AI milestones, the current wave in poultry processing showcases AI's maturing ability to tackle complex, variable biological systems, moving beyond the uniform product handling seen in simpler industrial automation. It mirrors the data-driven transformations observed in finance and healthcare, applying predictive analytics and complex problem-solving to a traditionally slower-to-adopt sector. The use of advanced capabilities like hyperspectral imaging for defect detection and VR-assisted robotics for remote control highlights a level of sophistication comparable to breakthroughs in medical imaging or autonomous driving, signifying a profound shift from basic automation to truly intelligent, adaptive systems.

The Horizon: What's Next for AI in Poultry

Looking ahead, the trajectory of AI in poultry processing points towards even more integrated and autonomous systems. In the near term, predictive scheduling will become even more granular, offering continuous, self-correcting 14-day forecasts for individual flocks, optimizing everything from feed delivery to precise harvest dates. Voice-activated assistants will evolve to offer more sophisticated, context-aware guidance, potentially integrating with augmented reality to provide visual overlays for tasks or real-time quality checks, further enhancing worker productivity and safety.

Longer-term developments will see AI-powered robotics expanding beyond current capabilities to perform highly complex and delicate tasks like advanced deboning and intelligent cutting with millimeter precision, significantly reducing waste and increasing yield. Automated quality control will incorporate quantum sensors for molecular-level contamination detection, setting new benchmarks for food safety. Generative AI is expected to move beyond recipe optimization to automated product development and sophisticated quality analysis across the entire food processing chain, potentially creating entirely new product lines based on market trends and nutritional requirements.

The pervasive integration of AI with other advanced technologies like the Internet of Things (IoT) for real-time monitoring and blockchain for immutable traceability will create truly transparent and interconnected supply chains. Innovations such as AI-powered automated chick sexing and ocular vaccination are predicted to revolutionize hatchery operations, offering significant animal welfare benefits and operational efficiencies. Experts widely agree that AI, alongside robotics and virtual reality, will be "game changers," driven by consumer demand, rising labor costs, and persistent labor shortages.

Despite this promising outlook, challenges remain. The high initial investment and the ongoing need for specialized technical expertise and training for the workforce are critical hurdles. Ensuring data quality and seamlessly integrating new AI systems with existing legacy infrastructure will also be crucial. Furthermore, the inherent difficulty in predicting nuanced human behavior for demand forecasting and the risk of over-reliance on predictive models need careful management. Experts emphasize the need for hybrid AI models that combine biological logic with algorithmic predictions to build trust and prevent unforeseen operational issues. The industry will need to navigate these complexities to fully realize AI's transformative potential.

Final Assessment: A New Era for Poultry Production

The advancements in AI for poultry processing, particularly in predictive scheduling and voice-activated assistants, represent a pivotal moment in the industry's history. This is not merely an incremental improvement but a fundamental re-architecting of how poultry is produced, processed, and delivered to consumers. The shift to data-driven, intelligent automation marks a significant milestone in AI's journey, demonstrating its capacity to bring unprecedented efficiency, precision, and sustainability to even the most traditional and complex industrial sectors.

The long-term impact will be a more resilient, efficient, and ethical global food production system. As of October 17, 2025, the industry is poised for continued rapid innovation. We are moving towards a future where AI-powered systems can continuously learn, adapt, and optimize every facet of poultry management, from farm to table. This will lead to higher quality products, enhanced food safety, reduced environmental footprint, and improved animal welfare, all while addressing the critical challenges of labor shortages and increasing global demand.

In the coming weeks and months, watch for accelerating adoption of advanced robotics, further integration of AI with IoT and blockchain for end-to-end traceability, and the emergence of more sophisticated generative AI applications for product development. Crucially, pay attention to how the industry addresses the evolving workforce needs, focusing on training and upskilling to ensure a smooth transition into this AI-powered future. The poultry sector, once considered traditional, is now a vibrant arena for technological innovation, setting a precedent for other agricultural and industrial sectors worldwide.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.